오늘은 FP8208-3.5A Synchronous Switch-Mode Single Cell Li-Ion Battery Charger에 대한 고찰을 해 보겠습니다.

FP8208은 3.5A Synchronous Switch-Mode Single Cell Li-Ion Battery Charger로 아래와 같은 특성을 지니고 있습니다.

The FP8208 is a highly integrated synchronous switch-mode Li-on Battery Charger. With few external components, FP8208 is well suited for a wide range of portable applications.

Charging current can be programmed by an external current sensing resistor.

With 720KHz switching frequency, FP8208 can use of small external components.

Other features include UVLO, automatic recharge, charge status indicators and battery temperature monitor.

-

Up to 3.5A Programmable Charge Current

-

Up to 92% Efficiency

-

Preset 4.2V Charge Voltage with ±1% Accuracy

-

Fixed Frequency Operation at 720kHz

-

Adjustable Charge Current using External Resistance Setting

-

No external MOSFET, or Blocking Diode Required

-

Switch-model Charger for single cell Li-Ion Batteries

-

Input Voltage Regulation

-

Automatic Recharge

-

2.9V Trickle Charge Voltage

-

C/10 Charge Termination

-

Battery Over-Temperature Protection

-

Over-Voltage、Over-Charge Current、Battery Short and Thermal Protection

-

Charge Status Indicators for No Battery and Charge Failure Display

Function Description

Operation

The FP8208 is a switch-mode battery charger designed primarily for charging single cell lithium-ion batteries.

The charger uses a constant-current/constant-voltage charge algorithm with programmable current.

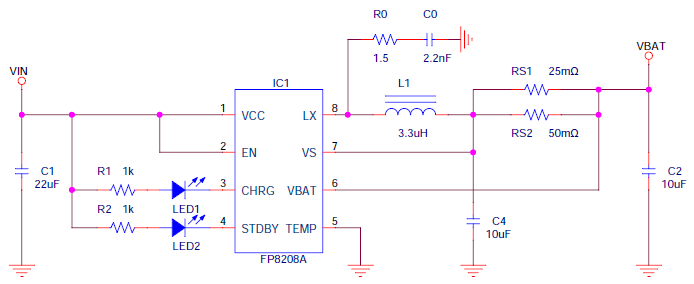

Charging current can be programmed externally with a single current sensing resistor between the VS pin and the BAT pin.

The final battery float voltage is internally set to 4.2V.

Normal Charge Cycle

A charge cycle begins when the voltage at the VCC pin rises above the UVLO threshold.

If the BAT pin voltage is smaller than 2.9V, the charger enter trickle charge mode.

In this mode, the FP8208 supplies approximately 1/10 the programmed charging current to bring the battery voltage up to a safe

level for full current charging.

When the BAT pin voltage rises above 2.9V, the charger enters constant-current mode, where the full programmed charge current

is supplied to the battery.

When the BAT pin voltage approaches 4.15V, the FP8208 enters the constant-voltage mode and the charge current begins to decrease.

When the charge current drops to 1/10 of the programmed value, the charge cycle ends.

Charge Current Programming

When the battery voltage exceeds the trickle charge threshold, the charger goes into the full scale constant current charge mode.

In constant current mode, the charge current is set by the external sense resistor RS and an internal 50mV reference.

Charge Termination

A charge cycle is terminated when the charge current falls to 1/10 the programmed value after the final float voltage is reached.

This condition is detected by using an internal filtered comparator to monitor the sense voltage.

When the voltage between the VS pin and the BAT pin falls below 10mV for longer then TTERM (1.8ms), charging is terminated.

The charge current is latched of and the FP8208 enters standby mode, where the input supply current drops to 70uA.

The FP8208 draws no current from the battery in standby mode.

This feature reduces the charge and discharge cycles on the battery, further prolonging the battery life.

Thermal Protection

An internal thermal feedback loop reduces the setting charge current to 1/3, if the die temperature

rises above a preset value of approximately 125°C.

This feature protects the FP8208 from excessive temperature and allows the user to push the limits

of the power handing capability of a given circuit board without risk of damaging the FP8208.

The charge current can be set according to typical ambient temperature with the assurance that the charge

will automatically reduce the current in worst case condition.

The FP8208 will shutdown automatically when the internal junction temperature reaches 150℃ toprotect both the part and the system.

The power MOSFET wake up when the junction temperature drops 50°C under the OTP threshold temperature.

Battery Temperature Fault Monitoring

In the event of a battery over-temperature condition, the charging control will turn off the internal

pass device and report a battery temperature fault on the TEMP pin.

Inside the FP8208, two internal voltage references VTEMP-H and VTEMP-L are fixed at 80% ×VCC and 45% ×VCC respectively.

As the TEMP pin voltage rises above VTEMP-H or falls below VTEMP-L, the FP8208 stops charging and indicates

a fault condition.

After the system recovers from a temperature fault, the device will resume charging operation.

For applications that do not need to monitor the battery temperature, short the TEMP pin to

the GND.

Under Voltage Lockout (UVLO)

An internal under voltage lockout circuit monitors the input voltage and keeps the charger in shutdown mode

until Vcc rises above the under voltage lockout threshold.

The UVLO circuit has a built-in hysteresis of 500mV.

Furthermore, to protect against reverse current in the power MOSFET, the UVLO circuit keeps the charge

in shutdown mode if Vcc falls to within 100mV of the battery voltage.

If the UVLO comparator is tripped, the charger will not come out of shutdown mode until Vcc raises

250mV above the battery voltage.

Short Circuit Protection (SCP)

When Battery voltage is lower than the short circuit protection threshold, the Hiccup mode is active and average current is around 50mA to assure opening the battery protective plate.

Normal operation mode recovers after fault condition is removed.

Manual shutdown

At any point in the charge cycle, the FP8208 can be put into shutdown mode when put the EN pin to the low-level voltage.

This reduces the battery drain current to about 10uA and the supply current to less than 70uA.

Automatic Recharge

Once the charge cycle is terminated, the FP8208 continuously monitors the voltage on the BAT pin using a comparator

with a 1.8ms filter time (TRECHARGE).

A charge cycle restarts when the battery voltage falls below 4V (which corresponds to approximately 80% to 90% battery capacity).

Application Information

Inductor Selection

Inductance value is decided based on different condition.

3.3uH to 4.7μH inductance value is recommended for general application circuit.

There are three important inductor specifications, DC resistance, saturation current and core loss.

Low DC resistance has better power efficiency.

Capacitor Selection

Use Low ESR capacitors are preferred to reduce the input inrush voltage, Ceramic capacitor of X5R and X7R are recommended, which have low equivalent series resistance (ESR) and wider operation temperature range.

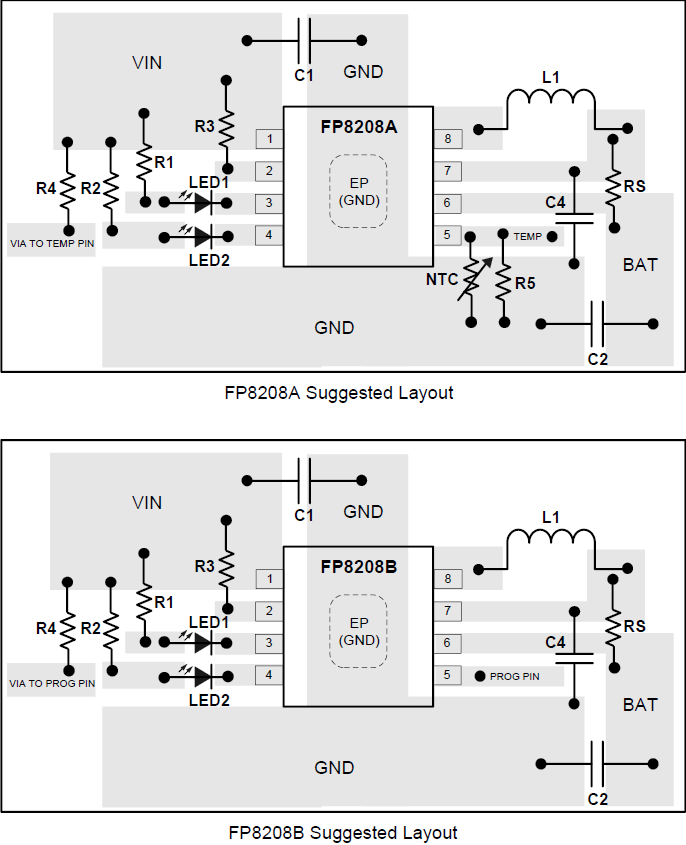

본 Chip은 FP8208A와 FP8208B 2개의 Type으로 나뉩니다.

차이점은 5번 Pin의 내용입니다.

1. FP8208A는 TEMP Pin으로서 Battery 온도를 Checking 하는 것입니다.

The values of R4 and R5 are set according to the battery temperature range and the value of

thermal sensitive resistor.

If the battery is equipped with NTC (Negative Temperature Coefficient)

thermistor and the temperature monitor range is TL~TH (TL < TH), then RT, the thermistor resistance,

decreases as temperature increases from TL to TH, means RTL> RTH.

The TEMP pin voltage can be calculated as:

Thus, this VTEMP decreases as the temperature increase from TL to TH.

To set proper R4 and R5 value for temperature protection, we set:

Where RTL and RTH are the thermistor resistances at TL and TH respectively.

So R4 and R5 can be derived as following:

where K1=0.45 and K2=0.8

2. FP8208B는 PROG Pin으로서 충전 전류를 Programing 하는 것입니다.

FP8208B는 Market에서 많이 사용하지않기때문에 추천드리지 않습니다.

Charging current can be programmed by the number of pulses on PROG pin.

충전 전류는 Application 제품 Micom의 high level pulse 수를 받아들여, 이미 정해진 약속에 의한 pulse 수에 의한 프로그래밍 해서 충전 전류를 결정합니다.

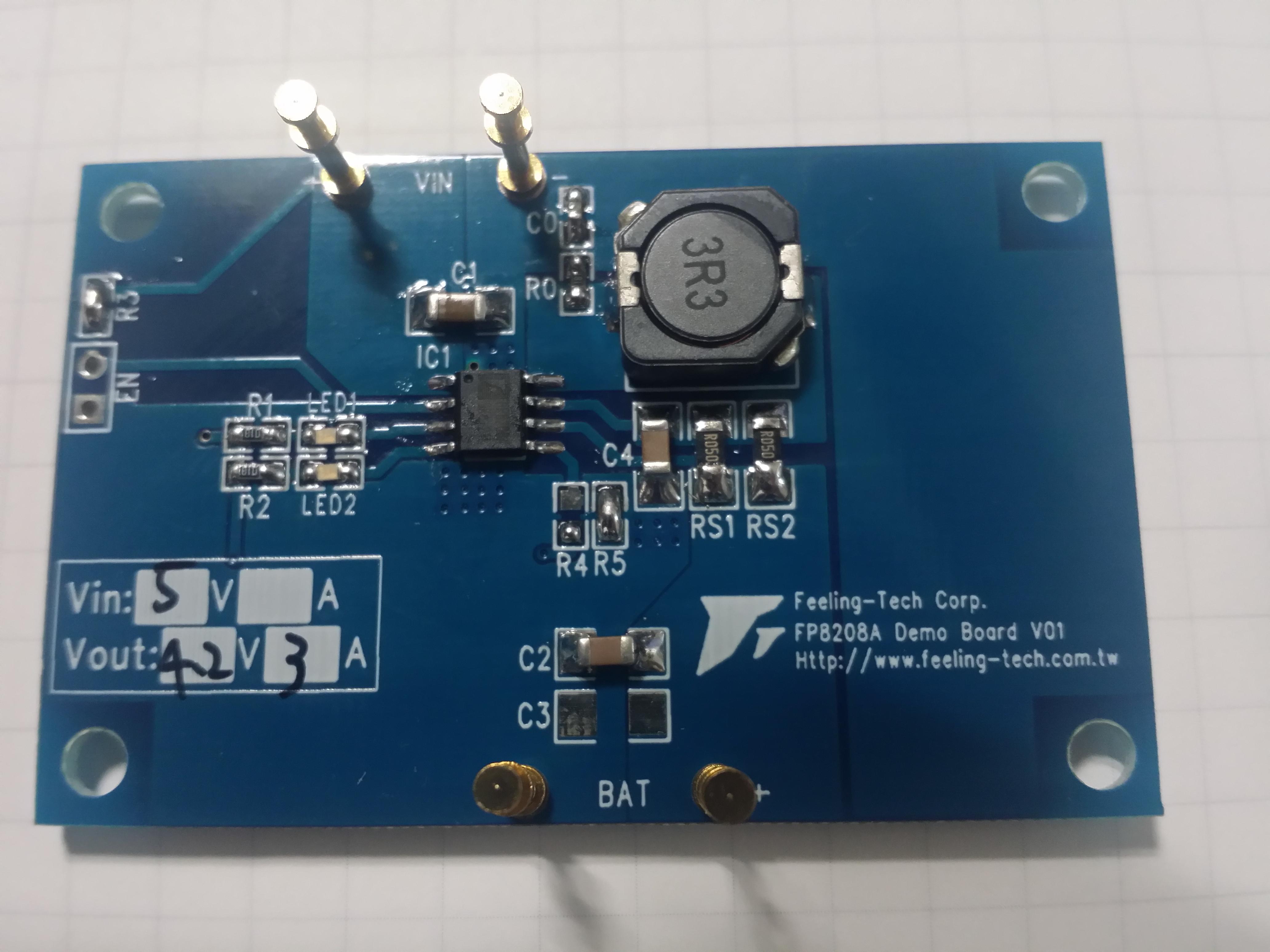

아래와 같은 Application에서 높은 효율 및 Chip 온도를 알 수 있습니다.

-

Vin=5V, Vbat=3.7V, 충전 전류=3A

-

Frequency=702.1kHz

-

Efficiency=91.72%

-

Temperature IC1=55℃

아래는 spec sheet에 있는 응용회로입니다.

Layout Considerations

1. The power traces, consisting of the GND trace, the LX trace and the battery trace should be kept short, direct and wide.

2. Layout switching node LX, inductor and diode connection traces wide and short to reduce EMI.

3. Place CIN nearby VCC pin as closely as possible to maintain input voltage steady and filter out the pulsing input current.

4. The GND of the CIN and COUT should be connected close together and directly to a ground plane.

5. Place RS nearby BAT pin and VS pin.

6. Use ceramic capacitor of X5R or X7R for C1,C2 and C4.

7. Charge Current is recommended for 0.5A to 3.5A.

'끝없는 Power를 위하여' 카테고리의 다른 글

| FP6161-1.5MHz, 1A Synchronous Step-Down Regulator에 대한 고찰 (0) | 2020.12.31 |

|---|---|

| FP6193-3A, 23V, 340KHz Synchronous Step-Down Converter에 대한 고찰 (0) | 2020.12.29 |

| SP687-X2 Capacitor Discharge IC에 대한 고찰 (0) | 2020.12.24 |

| FP6153-3A, 36V,Synchronous Step-Down Converter에 대한 고찰 (0) | 2020.12.24 |

| FP6151-5A, 36V, Step-Down Converter에 대한 고찰 (0) | 2020.12.24 |